The company claims that their carbon fiber 3D resin will be at least twice as strong as standard resin, pound for pound.

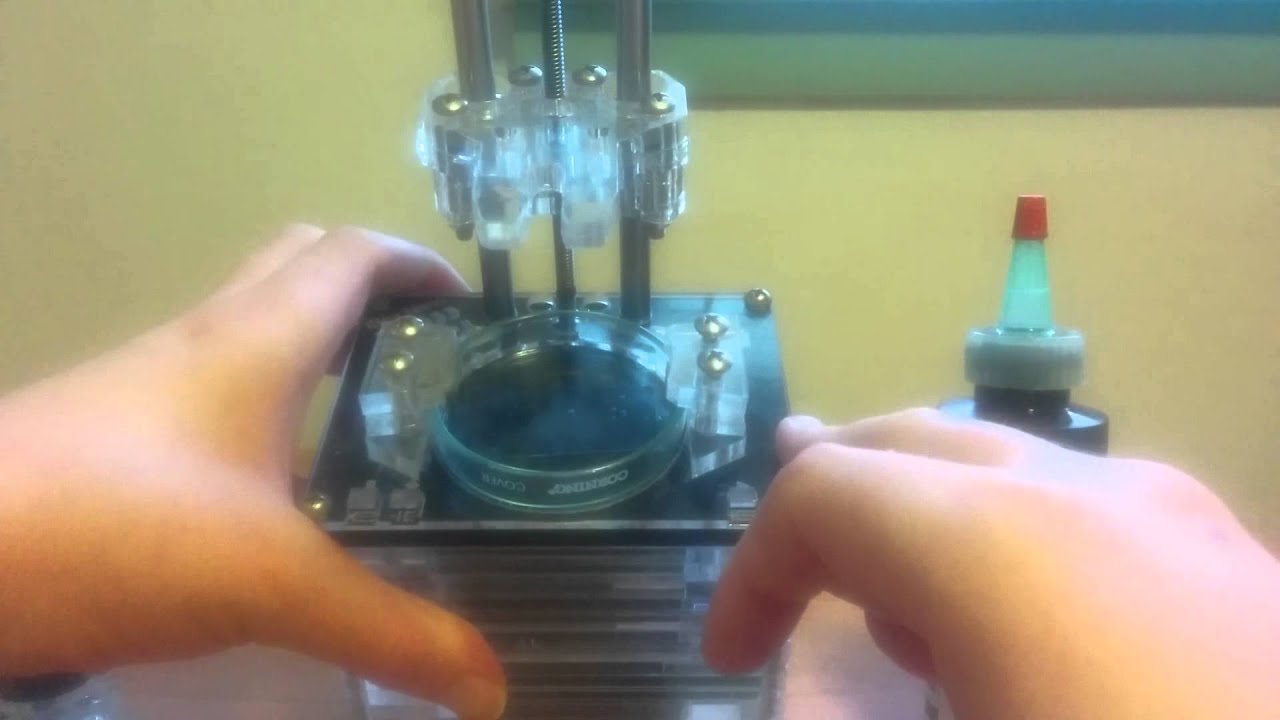

IBox has not finished conducting each of the measurements for their carbon fiber resin printing, but has reported a shore hardness of 90.5D, an estimated shrink of ~3%, an estimated viscosity of ~90cP and an estimated density of ~1.1g/cm 3. However, earlier this week we reported on a study carried out at the University of California which showed 3D printed components made using a resin 3D printer to be far more toxic than components printed in plastic. After taking a close look at photographs showing items printed using the Macro, it seems hard to argue with iBox’s claims about the printer’s superior resolution. iBox points to features like higher resolution, less banding, lower noise and thermal footprint as reasons to opt with a resin 3D printer. There are pros and cons to using a resin 3D printer over other traditional plastic 3D printers. The 3D printer itself weighs 10lbs, and measures 9 X 6 X 14”, with a build volume almost equivalent to Formlabs’ market-leading Form 1 SLA 3D printer. The machine also operates autonomously over WiFi using its internal Linux computer, and has a feature size of 100-145 microns on the X-Y axis and 5 microns on the Z axis. Of all commercially available 3D resin printers, the macro reportedly has the largest build area to device size ratio and consumes the least amount of power. The Kickstarter page makes some impressive claims for the Macro. All of the cheapest “super early bird” specials have been snapped up, but backers of the Kickstarter campaign can still receive a Macro 3D printer for an early bird $999 pledge. IBox Printers is billing the Macro as the “least expensive full-sized desktop 3D resin printer on the market”. The iBox Nano was a small, least expensive 3D resin printer, whilst the new Macro model promises a wider range of filament options and improved product strength.

iBox has successfully used the crowdfunding platform before, having raised an impressive $456,953 in 2014 to bring its iBox Nano into production. The company has set a target of $200,000 for the campaign, with over $25,000 currently raised and 33 days left to run. The 3D printer, which allows users to 3D print with both standard colour resins and carbon fiber resins, promises “the benefits of resin with the strength of steel”. IBox Printers has launched a Kickstarter campaign for its new iBox Macro 3D Resin Printer, which the company claims is the first-ever carbon fiber resin 3D printer.

0 kommentar(er)

0 kommentar(er)